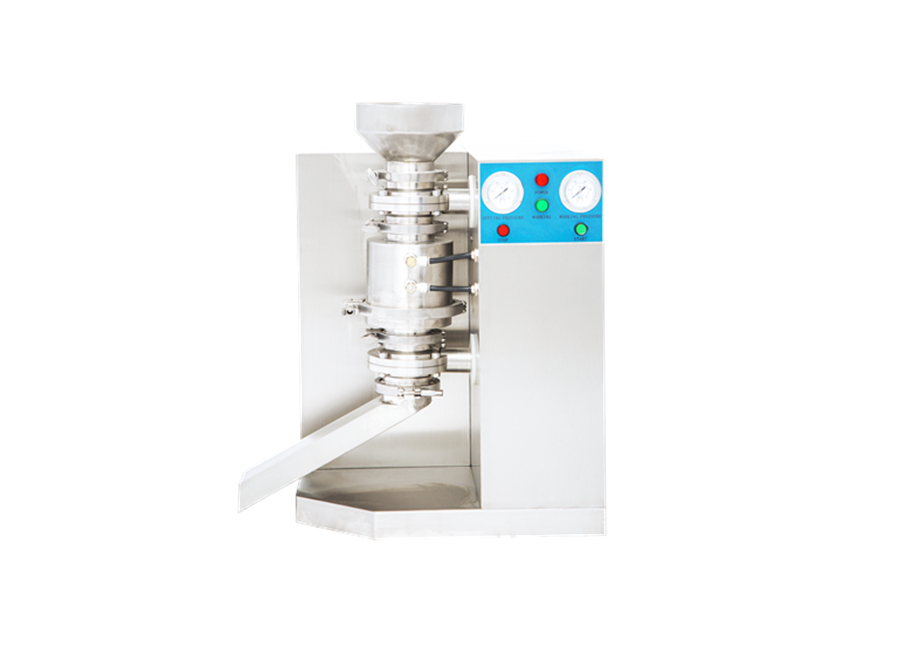

CS series vacuum capsule separating machine is the best partner of capsule filling machine, and the best tool for recovery and reuse powder. The recovery process of powder fully meets the requirements of GMP and the equipment meets the requirements of 21CFR-part211D, it is good helper of capsule filling workshop.

CS series vacuum capsule separating machine using the jet vacuum principle to convert external gas source supply of compressed air to generate high-frequency pulse vacuum, in a period of time, high frequency pulse vacuum continued to vacuum drawing the capsules in the working chamber , capsule under the action of pulse vacuum by drawing gradually open, after capsule body and capsule cap separated, the inside powder can be spilled out. Since the capsule is separated by a vacuum flexible force rather than a mechanical force, the capsule remains intact and does not produce any shell fragments.

In the whole process, the powder does not touch any mechanical parts, and is not contaminated by any, the return powder is the original powder; For different types of capsules, there is no need to change the mold, no need to adjust, maintenance-free design, you just easy to use.

1. No broken capsule shell: The capsule shell is not broken, there is no capsule shell fragments in the powder, the powder is clean, the return powder is the original powder, fully meet the requirements of GMP.

2. High recovery rate: The open rate of all types of capsules can reach more than 95%, and the recovery rate of powder after the secondary separation of powder shell is more than 98%.

3. No mold change: Suitable for all types of capsules, 00#~5# and safe capsule can be, do not need to change the mold, the equipment does not need to make any adjustment.

4. Easy to clean: Reasonable design, simple structure, good sealing, easy to disassemble and assemble, the powder is sealed and collected during operation, no overflow, all parts that contact with powder can be quickly disassembled and assembled by hand.

5. Easy to use: There is no need to adjust, lubricate and maintain the equipment at any time. Small volume, does not take up space, equipped with PU casters, easy to move and place.

6. High efficiency: Tens of thousands of capsules, ten minutes can all recover the powder, shorten the recovery and treatment time, avoid the powder to be exposed to the air for a long time, reduce the risk of powder pollution.

7. No pollution: When the capsule open, the powder only contacts with air, and there is not a risk that the mechanism metal wear debris will be mixed with the powder, and there is no risk of lubricating grease pollution, which will never cause any pollution to the recovered drug.

8. Care for drug: Vacuum principle, mechanism parts will not extrusion and damage capsule powder, pellets, particles, tablets and so on remains the same.

9. Strong Adaptability: In addition to the normal appearance of capsule, all kinds of deformed and damaged capsules, such as deformation, scald, damp and agglomerated powder, can be treated.

|

Model |

CS-mini |

CS1 |

CS2-A |

CS3 |

CS3-A |

CS5-A |

|

Work Efficiency |

500pcs/min |

700pcs/min |

3000pcs/min |

1000pcs/min |

1000pcs/min |

5000pcs/min |

|

Operation Panel |

Buttons |

Buttons |

Buttons |

Buttons |

Touch Screen |

Touch Screen |

|

Working Mode |

Semi-auto |

Semi-auto |

Semi-auto |

Auto |

Auto |

Auto |

|

Power Supply;Air Supply |

AC220V 50HZ ;0.6~0.8Mpa |

|

Dimensions |

607x310x553 |

450x600x650 |

840x420x490 |

500x400x1550 |

500x400x1550 |

650x700x1830 |

|

Weight |

45kg |

55kg |

140kg |

80kg |

80kg |

180kg |