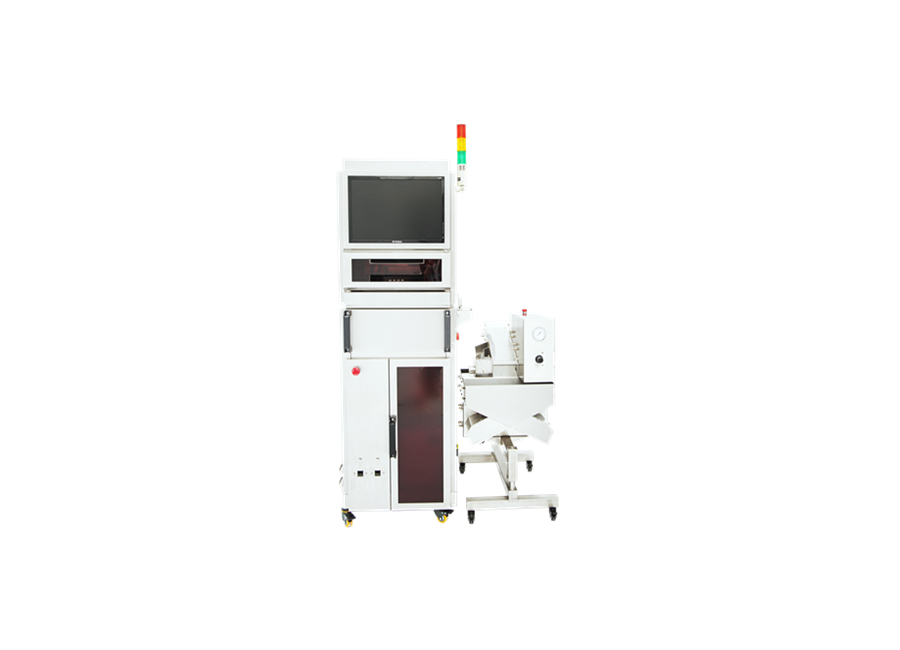

CVS is connected with all types of capsule filling machines and tablet press machine, and through online high-frequency sampling and weighing, it constantly monitors the weight variation of capsule and tablet as well as the operation status of capsule filling machines and tablet press machine. When the grain weight is found to exceed the standard, immediately alarm and automatically store the unqualified samples separately.

At the same time, CVS automatically generates a variety of data records, statistics, documents and control charts that required for quality management, with record query and automatic printing functions. In terms of data management, it fully complies with the highest requirements of EU cGMP and GMAP5, strictly complies with the provisions of US FDA 21CFR-PART11, and has the functions of three-level password access system, electronic record electronic signature, audit tracking, etc. to fundamentally ensure the data integrity of drug production process.

The detection for batches and die hole of CVS is more powerful function, with logic judgement ability. When the excessive grain weight is found, the detection for batches of CVS can immediately isolate the product batches with the risk of grain weight, so as to ensure that the qualified products batches must be qualified, and those with abnormal grain weight will be isolated in the risk product batches; the die hole detection functions of CVS, can even indicate every excessive grain capsule or tablet which detect by CVS and is from which die of capsule filling or tablet press machine, its advanced function of SPD(statistics prevention diagnosis), to provide an absolute advantage over than methods to solve the problem of grain weight deviation.

CVS makes the grain weight of capsules and tablets and the operation condition of capsule filling machine and tablet press machine constantly under the strict and effective monitor, can not only discover the problem of grain weight differences, immediately alarm, isolate risk product batches timely, and even be directly to find out the source of the problem, at the same time CVS can realize remote monitoring on the production field, can real-time understanding the condition of production site anywhere anytime, which is the clair eye and wind-accompanying ear of the production and quality management personnel.

As a way of quality control, CMC checkweigher is the result control of capsules and tablets quality, the difference, CVS is a process control of quality, is the powerful tool for discovering problem and finding problem, is a set of strong quality management system, is the effective ground tool of SPC quality management concept, but also it is the effective means of product quality.

At the same time, CVS can also be used in the production of hollow capsules to monitor the grain weight of hollow capsules offline or online in real time. All types of capsules are common, and there is no need to change the mold. But it has no function of detection for batches and die hole detection.

1. Connecting with capsule filling and tablet press machine

2. Level 3 password to log in to the operating system

3. The history parameter of product recipe is called flexibly

4. Timed automatic check the precision electromagnetic balance

5. High-frequency sampling inspection at predetermined time intervals

6. Take a predetermined number of samples and weigh them one by one

7. Accurate weighing and automatically records the data of each grain

8. Draw the grain weight control curve in dynamic real - time

9. Strictly monitor according to preset alarm conditions

10. Print the inspection report of grain weight difference at any time

11. Immediately alarm if the weight exceeds standard

12. If the situation is serious, then stop tablet press and filling

13. Store good and bad products separately automatically

14. Automatic section and effectively isolates risk products

15. Real-time remote monitoring of production site

16. Build unmanned workshop to realize industry 4.0

17. Optional SPD statistical process diagnosis

18. Directly display the specific mold hole of grain weight deviation

19. Possess the powerful data information statistics function

20. CPK was calculated to draw the normal distribution of particle weight

21. Data saved permanent for query invocation

22. Electronic record electronic signature of 21CFR-11

23. Convenient for quality retrospectives, with audit trails

24. Comply fully with FDA data integrity

25. Conform to the highest requirements of cGMP GAMP5

26. Can pass the computer system verification smoothly